Stable, Like a CAMEL

Important Notice:

Our company name is "Shenzhen Camel Die". Our email address is @cameldie.com.

Please note that "Camel Die" is a separate entity and is not affiliated with us in any way.

We urge our customers and partners to verify the correct contact information to avoid any confusion or miscommunication.

SHENZHEN CAMEL DIE LIMITED provides high-quality die casting mold design, stable mold development, and mold production export from China to North America & Europe. One of the worldwide leading mold manufacturers specializing in high pressure die casting (HPDC) mold build in-house. Currently, our factory has 15 sets of CNC machines and the primary material covers aluminum alloy, zinc alloy, and magnesium alloy. In addition, one-stop manufacturing service for all industrial applications, such as automotive, telecom equipment, electrical appliances, mechanical, motorcycle accessories, lighting, home appliances, medical instruments, aerospace, and machinery industries, etc.

We are also ISO 9001:2015 and IATF 16949:2016 certificate company.

Why choose us

Communication:

24 Hours Online Service ( China/USA teams)

Customer Service Team Works From Shenzhen, China, and Nashville, TN

Professional Service:

Working In The Mold Industry For More Than 12 Years

Management:

With Rich Experience From Designing, Processing, Mold trials, and Shipment

Mature Project Management System Reduce Cost

Short Lead time:

On-Time Delivery Rate At 97.14%

Efficient Trim Die Reduce Waste Materials

Longer Lifespan:

The Mold Life Of Aluminum Die Casting Molds Can Reach 200,000 Shots

The Success Rate Of The First Test Can Be Up To 96%

Effective:

Quotes And DFM Will Be Provided Within 24 Hours

The Mold 3D Drawings Are Provided Within 3 Days After Confirmation Of DFM

Honor:

Had Passed The ISO 9001:2015 and IATF 16949:2016

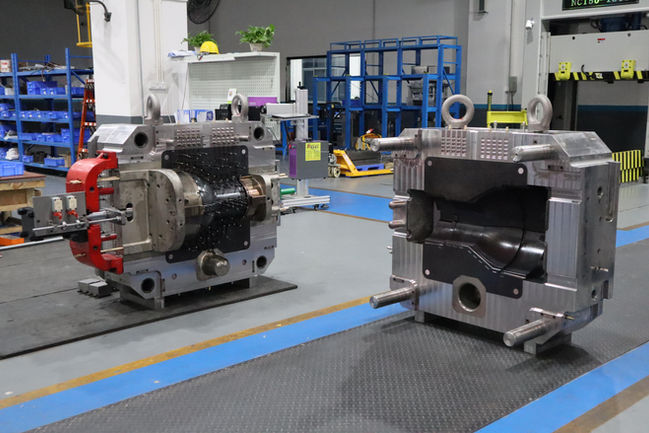

CUSTOMIZED MOLD DISPLAY OF CAMEL

The temperature of the aluminum alloy melt is usually around 1202~1292°F. The mold life should be focused on whether mold sticking and early dry cracking of the mold cavity occur. At present, General used steels included: 4Cr5MoSiV1 (H13), 4Cr5MoSiV (H11), 3Cr2W8V, and new steel grades Y10 and HM3.

The melting point of magnesium alloy is 1202°F. Die casting has a good molding feature. The tensile strength of magnesium alloy castings is equivalent to that of aluminum alloy castings, generally up to 250Mpa, up to more than 600Mpa. Compared with aluminum alloy, magnesium alloy has lower hot melt, and its iron content is also very low. Therefore, the mold has a longer life.

The melting point of zinc alloy is 752~806°F, and the surface temperature of the zinc alloy die casting mold cavity will not exceed 752°F. The materials generally used to manufacture structural steels 40Cr, 30CrMnSi, 40CrMo, etc. Alloy mold steels 5CrNiMo, 5CrMnMo, 4Cr5MoSiV, 4Cr5MoSiV1, 3Cr2W8V, CrWMn, etc.

Long tool life to reduce the setup time and waste materials.

Mold trials ranging from 280 tons to 3000 tons( 280T, 350T, 500T, 800T, 1250T,1650T, 3000T), and 12-15 sets of big die casting dies per month.

High Pressure Aluminum Alloy Die Casting Mold Case:

Product Parameters

Product Material: A380

Product Size (LxWxH): 443.97X469.89X243.6

Product Industry: Casino industry

Qty Of Cavity: 1*1

Qty Of Slider: 2

Mold Type: 2-Plate mold

Machine Tons: 1650T

Mold Size (mm): 1180X1050X871

Lead Time: 40 days

CAMEL's first factory, located in Dongguan city with 5,400 square meters supplies a capacity of around 300 sets per year. And the second factory, estimated in 2019 located in Huizhou city with 6,100 square meters to build about 240 sets of large molds per year. Essential equipment for die casting mold manufacture including CNC, EDM, WEDM, Fixtures, CMM, OMM, Die Spotting Machine, Oil Temperature Machine, and Mold Trial Machine.

CAMEL has 4 locations in total: 2 factories for die casting dies mold manufacturing respectively, 1 engineering office, and 1 sales office, with around 140 people in total.

ONE OF THE WORKSHOPS IN CAMEL HUIZHOU FACTORY

We offer you fast, affordable, reliable service while also providing your company with first-rate quality products. We understand that our customers need both quality and service to manufacture their top-quality products. With this understood, we will exceed our customers' expectations at a fantastic price.

CAMEL IS A PROFESSIONAL DIE CASTING MOLD MANUFACTURER AND SUPPLIER IN CHINA.

OUR ENGINEER TEAM WITHIN MORE THAN 12 YEARS OF TOOL AND DIES DESIGNING EXPERIENCE!